+86 15633683072

1. PLC control system, can store up to 100 groups welding programs, each group of welding program can be divided into 1-12 paragraphs. The operating interface uses the LCD10.1 touch screen, easy to setting the programs.

2. Adopting OTC brand DT300PⅡmodel DC inverter pulse power source, high welding efficiency, stable arc, finished welding effects will be beautiful and strong.

3. Water cooling system, ensure the machine can keep working with long time.

4. The trolley type designing, easy to move.

5. Water, electric, gas connect joints are connected conveniently, the machine has engine start function.

a) Equipment structure:

a) Equipment structure:

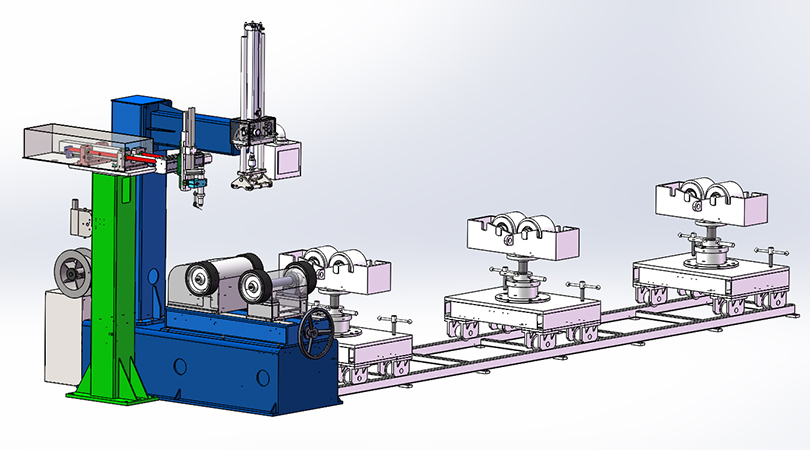

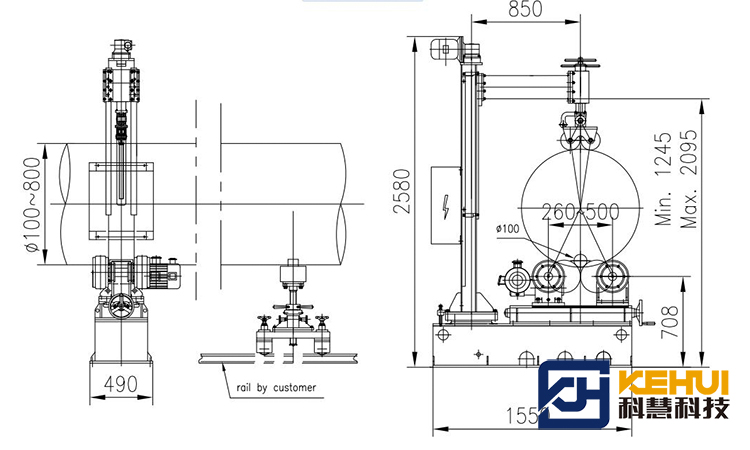

The equipment includes roller positioners, pipe centering support, welding actuator, welding system, and control system.

b) Operating Principle:

Cleaning the pipe end, beveling the pipe end with standard technology, ensure the unfitness of pipe butt joint is no more than 1mm, and it needs spot welding firstly.

| Model | KH Orbital 300A | |

| Control Method | - | IGBT Inverter |

| Rated Input voltage|Phase No. | - | AC 220V/380V±10% Three Phase |

| Input Power Frequency | Hz | 50/60 |

| Rated Input Capacity | KVA/KW | 9.0/5.9 |

| Rated Input Current | A | 300 |

| Suitable Pipe OD | mm | φ50-800mm (customized) |

| Pipe thickness | mm | 5-25mm |

| Rated Unload Voltage | V | 65V |

| Rated Load Sustained Rate | % | 60 |

| Rated Welding Voltage | V | 19V |

| Range Of Input Current | A | 4 - 300 |

| Initial Current | A | 4 - 300 |

| Pulse Current | A | 4 - 300 |

| Ending Current | A | 4 - 300 |

| Welding Wire Dia. | mm | φ0.8, 1.0, 1.2, 1.6 |

| Wire feeding speed | mm/min | TIG, 0-1500mm/min |

| MIG/MAG, 50-3000mm/min | ||

| Rise Time Of Current | S | 0 - 20 s |

| Fall Time Of Current | S | 0 - 20 s |

| Pre-flow Time Of Gas | S | 0 – 20 s |

| Lag Time Of Stopping Gas | S | 0 - 20 s |

| Pulse Frequency | Hz | 0.5 - 30 |

| Pulse Width | % | 5 - 95 |

| Memory Parameters Group | - | 1 – 100 group |

| Each set can segments | - | 1 – 12 segments |

| Cooling Method | - | Water cooling |

| Size(L*W*H) | mm | 900*700*1100 |

| Weight | kg | 90 |

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com